Vision System

Welcome to the future of quality control and automation: Machine Vision Systems. In today's rapidly evolving industrial landscape, businesses are constantly seeking ways to enhance efficiency, accuracy, and productivity. Enter machine vision – a revolutionary technology that empowers industries across the globe to achieve unparalleled precision and reliability in their operations.

What is a Machine Vision System?

A machine vision system is an advanced technology that enables automated inspection, measurement, and analysis of objects or processes using cameras, sensors, and artificial intelligence algorithms. By mimicking human vision capabilities, these systems can perceive, interpret, and make decisions based on visual information with remarkable speed and accuracy.

Key Components of a Machine Vision System:

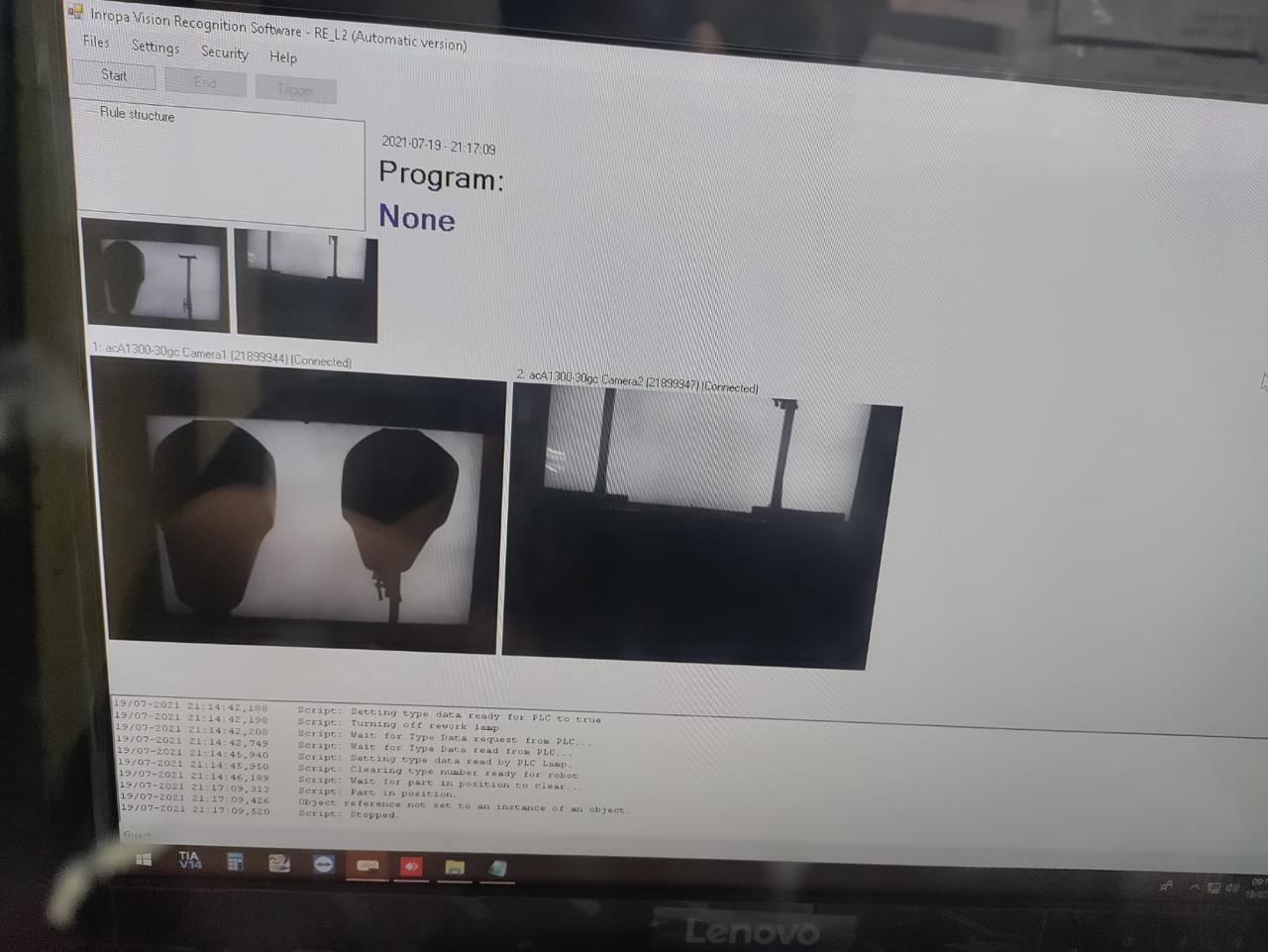

- Cameras: High-resolution cameras capture images or videos of objects or processes to be analyzed.

- Sensors: Additional sensors may be integrated to gather supplementary data such as temperature, humidity, or pressure, providing comprehensive insights.

- Processing Unit: Powerful processors process the -captured data, applying sophisticated algorithms to extract valuable information.

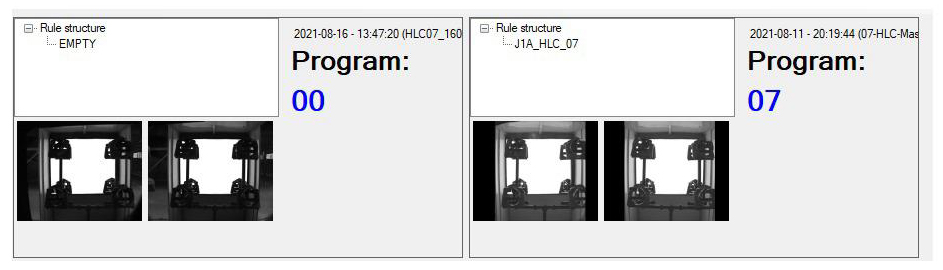

- Software: Customized software applications enable the system to interpret images, detect defects, measure dimensions, and perform other tasks according to specific requirements.

- Communication Interface: Machine vision systems often feature interfaces for seamless integration with other equipment or networks, facilitating real-time monitoring and control.

Applications of Machine Vision Systems:

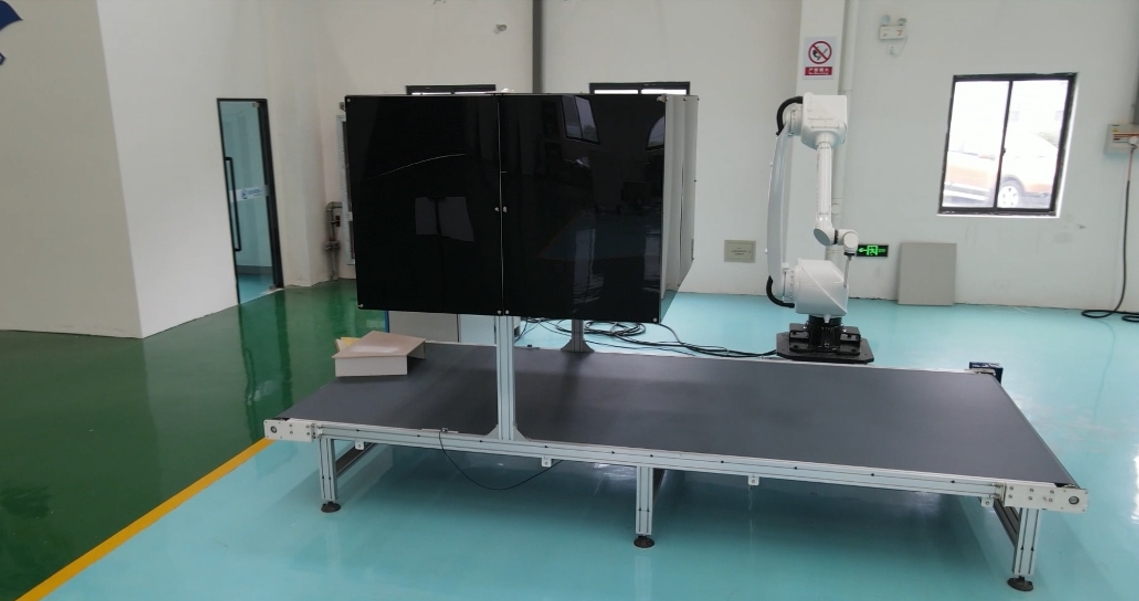

- Quality Control: Machine vision systems excel in detecting defects, inconsistencies, or deviations in manufactured products, ensuring adherence to stringent quality standards.

- Assembly Verification: By analyzing images of assembled components, these systems verify correct assembly, placement, and alignment, minimizing errors and rework.

- Barcode and Text Reading: Machine vision systems accurately read and decode barcodes, serial numbers, and text on labels, packages, or products, streamlining logistics and inventory management.

- Dimensional Measurement: Precise measurement of dimensions, angles, or shapes of objects enables quality assurance and process optimization in manufacturing.

- Robot Guidance: Machine vision guides robotic systems in performing intricate tasks such as pick-and-place operations, welding, or sorting with unmatched precision and flexibility.

Benefits of Machine Vision Systems:

- Enhanced Quality: Consistent and reliable inspection ensures superior product quality and customer satisfaction.

- Increased Efficiency: Automation of repetitive tasks reduces human error and accelerates production processes, leading to higher throughput.

- Cost Savings: Reduced scrap, rework, and labor costs contribute to significant savings over time, enhancing profitability.

- Adaptability: Machine vision systems can be tailored to meet diverse application requirements, providing versatility across industries.

- Data Insights: Captured data and analytics offer valuable insights into production trends, enabling informed decision-making and process optimization.

RESULT:

In a world driven by innovation and efficiency, machine vision systems stand at the forefront of technological advancement, revolutionizing industries with their unparalleled capabilities. Whether it's ensuring product quality, optimizing manufacturing processes, or enhancing operational efficiency, these systems empower businesses to stay ahead in today's competitive landscape. Embrace the power of machine vision and unlock a future of precision, reliability, and success.

Ready to elevate your operations with machine vision technology?