Simulation

In the dynamic landscape of industrial operations, maximizing efficiency and ensuring reliability are paramount. Industrial equipment simulation emerges as a transformative solution, offering a virtual playground for engineers and operators to fine-tune processes, optimize performance, and mitigate risks before implementation in the real world.

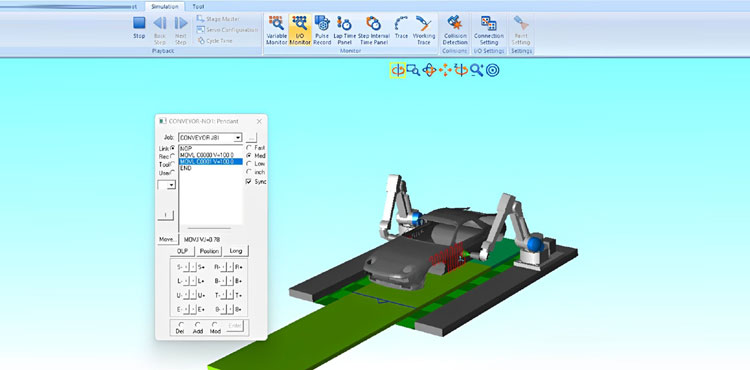

At its core, industrial equipment simulation involves the creation of virtual models that mimic the behavior of physical machinery, systems, and processes. These simulations utilize advanced algorithms and modeling techniques to replicate real-world conditions with remarkable accuracy. From manufacturing plants to logistics centers, simulation technology revolutionizes the way industries operate, offering a multitude of benefits:

- Optimization: By simulating various scenarios and parameters, engineers can identify optimal settings to enhance equipment performance and productivity. Whether it's adjusting production line speeds, optimizing energy usage, or streamlining logistics, simulation empowers businesses to achieve peak operational efficiency.

- Risk Mitigation: Implementing new equipment or processes carries inherent risks. Industrial equipment simulation allows stakeholders to assess potential risks and vulnerabilities in a controlled environment, minimizing the likelihood of costly errors or downtime. From identifying potential bottlenecks to evaluating safety protocols, simulation provides invaluable insights for risk management.

- Cost Reduction: Traditional methods of equipment testing and optimization can be time-consuming and resource-intensive. Simulation technology accelerates this process, enabling rapid prototyping and iteration without the need for physical prototypes. By reducing reliance on trial-and-error approaches, businesses can save significant time and resources while maximizing returns on investment.

- Training and Education: Simulation serves as a powerful tool for training personnel and educating stakeholders on complex industrial processes. From novice operators to seasoned engineers, interactive simulations offer a risk-free environment to learn and refine skills, fostering a culture of continuous improvement and knowledge sharing within organizations.

- Adaptability and Flexibility: In today's fast-paced industrial landscape, adaptability is key to staying competitive. Industrial equipment simulation allows businesses to anticipate and adapt to changing market demands, regulatory requirements, and technological advancements with agility. Whether it's reconfiguring production lines or optimizing supply chain logistics, simulation empowers businesses to stay ahead of the curve.

As industries continue to evolve and innovate, the role of industrial equipment simulation will only grow in significance. By harnessing the power of virtualization, businesses can unlock new levels of efficiency, reliability, and competitiveness in an ever-changing world. Embracing simulation technology isn't just about optimizing processes—it's about shaping the future of industrial excellence.