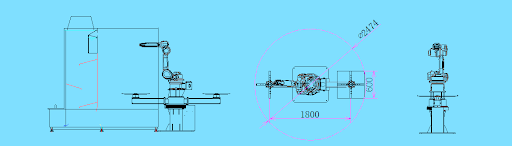

Rotary Table

Welcome to our guide on the role of rotary tables in optimizing robotic liquid painting booths. In today's industrial landscape, precision and efficiency are paramount, and rotary tables play a crucial role in achieving these objectives.

Understanding Rotary Tables

Rotary tables are key components in liquid painting booths, providing rotational movement for optimal paint application. Integrated seamlessly into robotic systems, they enable precise manipulation of workpieces, ensuring uniform coverage and high-quality finishes.

Benefits of Rotary Tables

Flexibility: Rotary tables allow workpieces to be rotated in multiple directions, adapting to various geometries for comprehensive paint coverage.

Efficiency: Automating workpiece rotation reduces cycle times and boosts production throughput, enhancing overall efficiency.

Precision Control: Ensures consistent paint application, minimizing wastage and adhering to strict quality standards.

Space Optimization: Compact yet robust, rotary tables optimize floor space utilization in painting booths.

Compatibility: Designed to integrate seamlessly with robotic systems, ensuring synchronized and efficient painting operations.

Applications

- Automotive: Used for impeccable finishes on vehicle components.

- Aerospace: Facilitates painting of complex aerospace parts with precision.

- Consumer Electronics: Ensures flawless finishes on electronic enclosures and components.

- Industrial Equipment: Enhances the visual appeal and durability of machinery and equipment.

Conclusion

Rotary tables are indispensable assets in robotic liquid painting booths, offering unmatched flexibility, efficiency, and precision. Whether in automotive, aerospace, electronics, or industrial sectors, they play a vital role in optimizing painting operations. Invest in rotary tables today to unlock the full potential of your robotic painting system.