SCADA and Control System

In the dynamic landscape of industrial operations, efficiency, reliability, and safety are paramount. SCADA (Supervisory Control and Data Acquisition) and control systems have emerged as indispensable tools, revolutionizing the way industries monitor, manage, and control their processes.

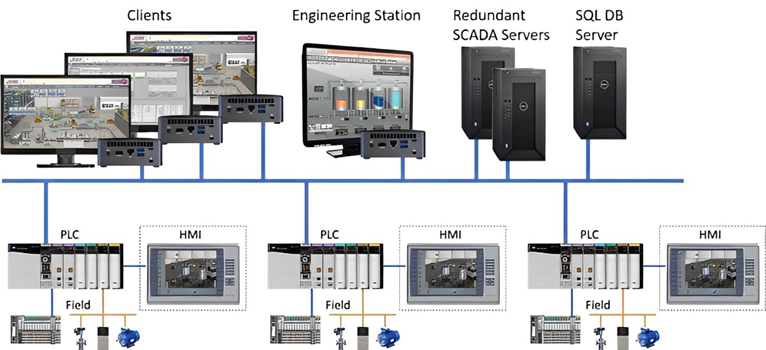

SCADA systems serve as the nerve center of industrial processes, offering real-time monitoring, control, and data acquisition capabilities. They integrate various sensors, PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), and other devices to collect and analyze data from remote locations. This enables operators to make informed decisions swiftly, ensuring optimal performance and minimizing downtime.

Key benefits of SCADA and control systems include:

- Remote Monitoring and Control: SCADA systems enable operators to monitor and control processes remotely, eliminating the need for physical presence on-site. This capability is particularly valuable for industries with distributed assets or hazardous environments.

- Data Visualization and Analysis: Through intuitive HMI interfaces, SCADA systems provide rich data visualization tools, allowing operators to interpret complex data easily. Advanced analytics features empower organizations to identify trends, optimize processes, and predict potential issues before they escalate.

- Enhanced Efficiency and Productivity: By streamlining operations and providing real-time insights, SCADA systems enhance overall efficiency and productivity. They enable proactive maintenance, reduce manual intervention, and optimize resource utilization, leading to cost savings and improved output.

- Scalability and Flexibility: SCADA systems are highly scalable and adaptable, catering to diverse industrial requirements. Whether managing a small facility or a large-scale operation, these systems can be customized and expanded to accommodate evolving needs seamlessly.

- Regulatory Compliance and Safety: Compliance with industry regulations and safety standards is critical for industrial operations. SCADA systems facilitate data logging, audit trails, and alarms, ensuring adherence to regulatory requirements and enhancing overall safety protocols.

- Integration with IoT and Industry 4.0 Technologies: SCADA systems play a pivotal role in the integration of IoT (Internet of Things) devices and Industry 4.0 technologies. By connecting disparate systems and devices, they enable seamless data exchange and facilitate the implementation of smart manufacturing initiatives

In conclusion, SCADA and control systems represent a cornerstone of modern industrial automation, empowering organizations to optimize processes, enhance productivity, and ensure operational excellence. As industries continue to evolve, embracing these technologies will be crucial for maintaining competitiveness, driving innovation, and achieving sustainable growth.